High-Level Project Summary

The concept is to directly harvest mechanical work from the thermal gradient to a core of phase change material using a Stirling cycle engine. This should have the benefit of reducing the thermal transfer to the phase change material while moving the rover. The stirling piston will have linkage to bend three body segments yaw-pitch-yaw of a minimal snake configuration. The Y-P-Y snake provides walking or rolling mobility as shown in the working demo. The snake configuration eliminates wheels, suspension, steering, motors.The phase change cold sink would house "normal" radios, sensors, compute, batteries.

Link to Final Project

Link to Project "Demo"

Detailed Project Description

The approach taken to reach the 60 day lifetime is not to rely on unproven technology, but instead to combine technology at a high TRL.

Large mass of PCM to meet 60 day lifetime

The Nasa resources identified that Phase Change Material (PCM) is likely to be used to increase the lifetime of landers to several hours. The mass of PCM could be increased to reach the 60 day lifetime. Typical PCM energy absorption capacity is 200KJ/Kg. The necessary mass of PCM was not analyzed in this project.

It should be noted that a core cooled by PCM would allow use of "normal" spacecraft systems: batteries, compute, radios, sensors.

Reduce PCM mass by converting some heat flux to mechanical work

The use of large masses of PCM results in a stable heat gradient that is further utilized by an efficient heat difference engine (Stirling configuration) for two purposes:

- The heat gradient can be converted directly to physical work for mobility purposes

- An efficient heat difference engine reduces heat flux to the PCM core when the energy is converted to physical work

The heat difference engine can be configured so that the entire outer surface (assumed to be spherical) of the rover is the hot side of the gradient. The cold side would be the PCM core.

Efficient Stirling engines can convert high percentages of the heat flux into mechanical energy.

This reduction of the heat flux to the PCM core would reduce the mass of PCM necessary to survive 60 days.

Since the extraction of work from the heat flux actually decreases the core heating, it is beneficial to continuously operate this process. The vehicle will be always on the move.

Movement system

The NASA AREE report explored wheeled and tracked mobility: However, there may be a better configuration to utilize direct mechanical power from the Stirling cycle engine.

The output of the heat difference engine would be any number of reciprocating pushrods with short throw but large force.

The work of Gonzales 2013 shows that a configuration 1 unit high x 1 unit wide x 3 units long and provided with 3 bending joints can crawl, walk, turn and roll. This is described as a 3 segment Yaw-Pitch-Yaw snake. Moreover, the bending motions required to achieve the various gaits are all purely sinusoidal which is a very good match to linking directly with the Stirling engine sinusoidal output. Three heat difference engine output pushrods linked one to each joint would provide mobility to the vehicle. (See the demo).

Space Agency Data

Nasa resources - Automation Rover for Extreme Environments

Hackathon Journey

The reference material is fantastic and is a pleasure to read.

References

https://en.wikipedia.org/wiki/Phase-change_material

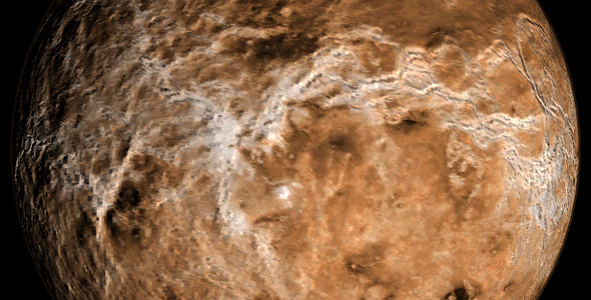

Team picture - Wikipedia commons

Nasa mechanical rover - identification of phase change material to extend lifetime of landers

Locomotion Principles of 1D Topology Pitch and Pitch-Yaw-Connecting Modular Robots, Juan Gonzalez-Gomez http://www.iearobotics.com/personal/juan/publicaciones/art16/download/cwr-chap24-Gonzalez_et_al.pdf

Tags

#hardware