Awards & Nominations

3D Prototype Design Ideas For Artemis IV has received the following awards and nominations. Way to go!

3D Prototype Design Ideas For Artemis IV has received the following awards and nominations. Way to go!

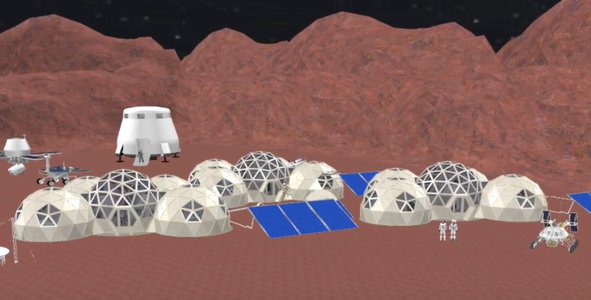

The 3D Prototype Design Ideas For Artemis IV team has created a composite 3D model that explains how NASA's Artemis IV team can successfully colonize the Red Planet and sustain a living environment through three geodesic dome structures that are produced by 3D laser printers using: thermoplastics, metals, and a basalt concrete hybrid called "mars-crete."This prototype solves the NASA Space Apps challenge by providing a detail oriented outline of what is required to sustain life on another planet, and how NASA can develop tools, textiles, habitats, spacesuits, and all of the necessary components of survival using current 3D laser printing technologies that have already been developed.

Hello, and welcome to "The 3D Prototype Design Ideas For Artemis IV" team!

We are a group of science enthusiasts, citizen scientists, and active members of respected STEM fields who are collaborating together to create an innovative 3D model that will help NASA further its Artemis IV goals of sending humans to Mars’ surface by 2030.

This project details the components necessary to survive on the lunar surface in the harsh, low-gravity conditions that Mars offers. In addition, we have also conducted Open-Source research within NASA and other respected aerospace organizations in order to determine what composite materials can be used to produce goods needed to sustain the Martian habitat via 3D printing devices.

Our submission presents a composite of innovative technological 3D rendering, inspirational storytelling, a plausible mission concept, thorough scientific research and data implementation, reasonable galactic impact and international collaboration between a highly precise group of knowledgeable team members.

OUR AIMS FOR THIS PROJECT:

1.Create an introduction video that details the requirement of living on Mars.

2.Take pictures of each product to create a featured section discussing the product's uses.

3. The most important and the foremost task is to put efforts and hard work together as a team to come up with a solution for colonizing the Martian surface with the best habitat and minimal galactic impact on the planet’s surface.

OBJECTIVES: The main goals of this project are:

1. Construct a replacement of the broken rover wheel.

2. Design multipurpose tools with the help of 3D laser printers.

3. Make the Martian grounds of Mars a livable habitat.

4. Utilize large amounts of Martian resources to sustain the colony.

______________________________________________________

Requirements From NASA Space Apps:

Construct tools and textiles for survival on Mars. A summary of the three printer build volumes (length x width x height) and their resolutions is provided below:

______________________________________________________

The Link To Our Website Is: www.colonizemars.co

The Link To Our Full-Length Documentary Is:http://youtu.be/ERzA4do6b-I

The Link To Our Demo Pitch Slideshow Is: https://docs.google.com/presentation/d/16_mPgCrbeWHnKT0hw58wra7oe3A8CamC3HLHhgkr8AE/edit?usp=sharing

The Link To Our Demo Pitch Video Trailer Is:https://youtu.be/5oaA_e9Ry3I

______________________________________________________

This documentary details the process of landing a crew of eight astronauts on Mars' lunar surface for NASA's Artemis IV mission, slated to begin its first mission by the end of 2022.

This 3D prototype design models a colony that can sustain itself for a mission spanning up to two years; with the possibility of future expansions extending its lifespan.

The model uses 3D laser printing devices that can create prototypes for tools, furniture, textiles, rovers, and the habitat's construction itself using up to three materials including: thermoplastics and silica-plastic hybrids, metals, and concrete-basalt hybrids called "mars-crete" that can be obtained through the resource-rich Martian soil.

______________________________________________________

The Incredible Team For This Project Is:

Madison C. Feehan:

- External Peer Reviewer and Executive Panelist For NASA NSPIRES; Data Analyst For European Space Agency (ESA) CERN x EGO-VIRGO Project; and Student of Athabasca University and Harvard University.

- Team Leader, Organizer, Transcriber, and Documentary/3D Graphics Developer.

Nawaf Rasheed:

- Mechanical Engineer at Saudi Aramco; MS Student at the University of Illinois Urbana Champaign (UIUC).

- Executive Researcher, Collaborator, 3D CAD Tool Designer, and Local Representative for the #Chicago location.

Vindhya Agarwal:

- Class 12th Student; Majoring In Science, Composite Technical Knowledge in Research, Astrophysics, Cosmology, and Programming (with experience using Java and Python).

- Key Executive Researcher, Collaborator, and 3D Tool Imagery Designer.

Jenan Bayari:

- Mechanical Engineer with JoVision, Graduate of Jordan University of Science and Technology.

- Lead Researcher for 3D Printing and Mars Terrain Challenges, and Key Executive Collaborator.

Dhanesh Nama:

- 3rd Year University Student Studying Product Design, Design in Lifestyle and Accessory Design, Composite Technical Knowledge In 2D Graphics and UX/UX, STEM Advocate For Studying Finite Life and the Infinite Universe.

- Key Researcher, 2D Tool Design Illustrator, and Collaborator.

Arunabh Mittal:

- Mechanical Engineer with TATA Advanced Systems Limited, Certified Solidworks Associate (CSWA) Dassault Systemes.

- Key Researcher, Collaborator, 3D CAD Tool Designer, and Website Developer.

________________________________________________________

Introduction To 3D Printing:

Three-dimensional printing is a developed manufacturing technology that produces complex shape geometries automatically from a 3D computer-aided design model through the layering method and without the need for traditional tools and dies.

3D printing has been used in various domains, such as medicine, education, art, and industrial sectors like aerospace, construction, home development, robotics, and the automotive industry because of the many advantages it has of rapid prototyping, reduction the cost, and the risk, good quality, accessibility, sustainability and many other.

In the aerospace industry, 3D printing is used to manufacture high-quality, lightweight, and complex engineering parts, which contributes to reducing the fuel and resources used. it has been widely applied to produce spare parts for some aerospace components such as engines. The engine’s part is easily damaged, which requires regular replacement. Therefore, 3D printing technology is a good solution to the procurement of such spare parts.

There is a wide choice of materials that can be used for 3D printing such as plastic, powders, metal, carbon fiber, graphite, and graphene. Nitinol, concrete, and paper, each have their own unique qualities that make them more suitable for specific use cases.

In this challenge three 3D printers are going to be used:

Plastic 3D printing:

Plastic is considered to be the most used material in 3D printing, because of its durability, elasticity, range of color options with different textures like matte or shiny textures, and environmentally friendly as we can use recycled plastic in printing.

Plastic products are commonly made with FDM printers “fused deposition modeling”, the 3D printer takes a spool of plastic filament, melts it, and extrudes it onto a tray to build the part layer by layer from the bottom up, the resulting parts are so tough.

There are four main types of plastics used in this process:

Can we produce plastic on Mars?

The production of plastics requires more energy than most types of mining and separation, as demonstrated by the embodied energy concept. However, it may be achievable in useful quantities from the non-edible biomass created by food production. The needed substances are in the Martian atmosphere: Carbon dioxide and water. So, with some additional energy, it should be possible to make plastics from thin air.

Metal 3D printing:

Metal 3D printing is widely used in aerospace and automotive industries because it allows complex metal parts to be produced at a relatively low price compared to traditional manufacturing processes. There are many technologies used to make metal products, one of them is DMLS” direct metal laser sintering”, which utilizes a variety of metal and alloy materials such as stainless steel, cobalt chrome, and aluminum to create strong, durable parts and prototypes and high-temperature applications. Another technology used is SLM “Selective Laser Melting”, the similarity between the two processes is that they both use a laser to scan and selectively fuse the metal powder particles, bonding them together and building a part layer-by-layer. Also, the materials used in both processes are metals that come in a granular form.

Are there any metals on Mars?

Apart from iron ore, the major ingredients normally required for steelmaking are coking coal, limestone, and oxygen-rich air, all of which are in short supply on Mars. However, the basic elements of steel – namely, iron and carbon – are available, which suggests that steel can be manufactured on Mars from local ingredients using new methods.

Also, many important elements have been detected. Magnesium, Aluminum, Titanium, Iron, and Chromium are relatively common in them. In addition, lithium, cobalt, nickel, copper, zinc, niobium, molybdenum, lanthanum, europium, tungsten, and gold have been found in trace amounts. It is quite possible that in some places these materials may be concentrated enough to be mined economically.

Concrete 3D printing:

Concrete is a composite material that consists of water, cementitious compound, and aggregate (sand, gravel, crushed stone, and similar substances) which we can find on mars. There are several benefits of using a concrete 3D printer rather than traditional manufacturing methods. It is faster, cheaper, safer, and more efficient, using a concrete 3D printer, construction can be completed to a significantly higher degree of resilience and geometric complexity.

A typical concrete 3D printer is designed to additively manufacture parts through material extrusion, consisting of a robotic arm, with one end attached to the printhead, and the other either to a gantry or crane-like robotic arm system.

____________________________________________________

Thank you so much to the NASA Space Apps team of innovators, participants, and judges! We are very privileged to have participated in this incredible international competition. Thank you for viewing our presentation.

Affiliate Links From International Space Agencies:

NASA:

Canadian Space Agency:

European Space Agency:

Indian Space Research Organisation:

Japan Aerospace Exploration Agency:

The 3D Prototype Design Ideas For Artemis IV project details what it will be like to live on Mars when NASA sends its Artemis IV crew to Mars’ surface.

OBJECTIVES: The main goals of this project are

1. Construct a replacement of the broken rover wheel.

2. Design multipurpose tools with the help of 3D laser printers.

3. Make the Martian grounds of Mars a livable habitat.

4. Utilize large amounts of Martian resources to sustain the colony

Our journey began at the time NASA announced the dates for the Space Apps Challenge 2022.

All of our team members were from different regions all across the world, however, we had the same common interest and motivation in mind to take this initiative forward by creating something new and innovative. Our team is a group of people with diverse skill sets and dedication; who are ready to give 110% in the face of any challenge.

The project started with a general zoom meeting among team members for brainstorming, then came the time we all had anxiously waited for: "the hackathon day". We did a superb amount of research on how to solve the challenge that we chose: Outfitting a Habitat on Mars: a 3D Print Challenge.

We came up with a bunch of ideas for how 3D printers can sustain a colony of eight astronauts on Mars. After analyzing and brainstorming, our team concluded we need to ease the life of astronauts on Mars and use the resources available there to construct our prototype. The habitat makes enough food, water, breathable air, and power to house a crew of eight astronauts.

We came up with the ideas like: A fully-developed Mars habitat designed to prioritize the daily activities of humans on Mars and create a series of tools, textiles, furnishing, and sample acquisition devices that they will require on Mars to easily sustain life.

Design as per the prioritized activities and requirements from the Space Apps challenge, we created a proposal that saves the time and effort of the Mars inhabitants. Our team designed the tools and accessories that will save space and reduce the loads of astronauts travelling to Mars via rockets.

Many of our designs are multitasking and readily-deployable. Everything we designed was cited with existing technology in mind. Our team ensured that our design fulfills the dimensional and material criteria of the challenge as well. The tools like carabiner, tool bottle, regolith sampling shovel, and rover replacement wheel and table (which multitasks as a conference table), could be very useful when astronauts begin exploring the red planet on the Artemis IV mission, slated for completion in around 2030 by NASA.

The inspiration for these tools are taken directly from NASA sources (linked in this project).

Coming to the rover wheel design: we explored various designs like using the waste products or taking inspiration from nature but to avoid unnecessary complexity, we designed a simple yet useful wheel which is easy to print with metals and plastics and can serve its designated purpose for a long time; which fulfills the main challenge requirement.

All the designs proposed by us are easy to build and assemble. We tried to propose some new technology such as: producing materials such as silicon-thermoplastic hybrids, using sand and soil to mix with concrete to reduce the amount of raw material used per print, etc… Hydroponics tech on Mars was also a key design element that allowed us to create a greenhouse, and an oxygenation process; making the entire design environmentally friendly.

On our journey, we took some inspiration from various databases and resource links. Through our work, we share what empowerment through innovation, creativity, and inclusion in space can look like. Each team member had a valuable perspective and an approach to things, and each person’s contribution is what composes the strong foundation of our team.

“Alone we can do so little; together we can do so much.” #NASA #SpaceApps #MakeSpace

References:

For 3D Modelling:

For Demo Pitch Slide and Brainstorming:

For Website Design:

For Video Production and Cloud Uploading:

For Research: (All Space Agency Data Is Cited Above)

Open-Source Research Data: (Including Text Research, Imagery, and 3D Design Inspiration)

#Artemis, #ArtemisIV, #Mars, #MarsColony, #SpaceTools, #RegolithSampling, #3DPrinter, #LaserPrinter, #3DGraphics, #Art, #NASA, #CLPS

Imagine you’re an astronaut who has newly arrived on the Red Planet. Your habitat has been pre-constructed for you, but, other than three 3-D printers, it doesn’t have most of the things you need to live and work. Your challenge is to design tools, furniture, and other items to assist you on your one-year mission.