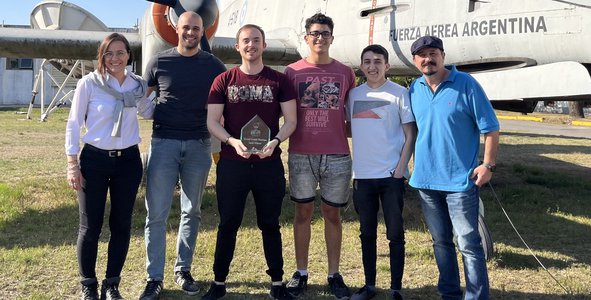

Awards & Nominations

HADES has received the following awards and nominations. Way to go!

HADES has received the following awards and nominations. Way to go!

The Project HADES (Human Advanced Device to Explore Space) proposes a solution to the challenge of designing an energy storage system capable of withstanding the adverse conditions present on Venus for 60 days. The solution proposed makes use of a Savonius wind generator mechanically coupled to a transmission for propulsion, taking atmospheric data, signaling and a coil spring, the latter serving as a mechanical energy reserve; while on the other hand there is a primary, rechargeable and high energy density Lithium - Sulfur battery which makes use of in situ resources and provides energy to the Rover's remaining systems.

Given that we see space as a strategic resource for the well-being of humankind, and planet exploration as a vital aspect of space, we created Project Hades to push further the things we are able to accomplish.

Project Hades is an energy storage system which gives a technical solution to the problem of providing necessary energy to power a surface lander Rover on Venus for a period of at least 60 days[2]. To accomplish this objective Project Hades makes use of several subsystems, each providing the energy to complete different tasks, which consist of a Savonius Wind Turbine, Mechanical Spring and Li-S Batteries.

Image: Venus taken by Magellan Venus Explorer © NASA/JPL [1]

Image: Venus taken by Magellan Venus Explorer © NASA/JPL [1]

Venus circulates just inside the earth's revolution orbit, thus it comes closest to the earth. Its diameter is 0.95 times that of the Earth, and its weight is 0.82 times. Therefore, both its size and weight are also very similar to that of the Earth. The inside structure is also believed to be very close to that of the Earth. Venus's crust from its surface to around 30 km consists of silicic acid. Beneath that crust, a mantle also comprised of silicic acid spreads out. At the center, there is a core made of iron and nickel. [1]

Image: Venus covered by thick clouds [1]

Image: Venus covered by thick clouds [1]

Venus has a very thick atmosphere which mostly consists of carbon dioxide (CO2.) Due to this atmosphere, a very strong greenhouse effect occurs, and the temperature on the surface of Venus is 460 degrees Celsius both during the day and night. This temperature is much higher than that of Mercury, which is closer to the Sun. In the atmosphere, clouds made of sulfuric acid particles spread out, and these clouds block sunlight from directly reaching Venus' surface. These clouds also cause sulfuric acid rain, but it evaporates before it arrives on the surface because of the extremely high temperature. On the upper layer of the Venus atmosphere, strong winds of 100 m/s, which take only one hour to circulate around Venus, blow. This wind is called a "Super Rotation." It is not known why such a strong wind blows as the rotation period of Venus is very slow. [1]

The energy storage system was designed taking into account the atmospheric conditions of Venus, the energy requirements of the Automaton Rover for Extreme Environments (AREE) and the materials necessary for the conditions. Therefore, the calculations and design are based on the information given by the Space Agencies.

The power estimate was made based on the Automaton Rover for Extreme Environments (AREE), which was provided by NASA. [2]

Figure 1: Power Estimation List

Power from the savonius generator is passed through a transmission and then divided: a fraction is geared to the wheels, and the other fraction is available to load a coil spring that is used to save mechanical energy and to balance wind power fluctuations, as the spring can store and supply mechanical energy, in accordance with the difference between generator speed and wheel speed. (Figure 1)

Figure 2: Drivetrain Diagram [2]

To accomplish this task, a differential adder is needed to add the separate rotary inputs into a single rotary output and to maintain constant power using the power stored by the coil spring in the case of having low wind speeds in which the wind turbine cannot provide the necessary power.

We expect the Wind Turbine to be primarily used to drive the rover, run communications systems, and other aspects that are required for day to day operations, we estimate that this requires around 16.39 w-h to operate. To supply sufficient power we designed a Savonius Wind Turbine, to calculate the dimensions of it we started by the general sustainability formula (see annex - eq.(1)).

Using the following values in (see annex - eq. (4)):

r= 90 1.225 [kg/m3]

𝛈= 0.12

V= 0.6 [m/s]

N= 0.17 [kW]

We obtain A= 0.12 square meters as the rotor’s frontal area. We believe the value being small will bring complications so we decided to use a rotor frontal area of 0.5 square meters, this way the turbine will produce more than enough energy to power the previously mentioned systems.

We chose Inconel 718 to build the Wind Turbine given the material's excellent properties at such adverse conditions found in the planet’s atmosphere [4], but we also see other materials such as 21/4Cr-1Mo Steel, Ti 6246 or 450 stainless steel as viable alternatives. Given Inconel 718 density of 8300kg/m^3 [4], we expect the Savonius Wind Turbine to weight around 70 kg.

A further advantage of using a wind turbine system is the ability to drive the wheels directly from the turbine, thus reducing power lost from storage. A direct drive system would result in approximately 65% transmission efficiency whereas losses are much greater if energy from the turbine is stored in a battery [2]. Also, another advantage of using the Savonius wind turbine relies in that it doesn't have the need of orienting itself to face the wind since it works independently of wind directions.

We propose a Inconel 718 coil spring[4] to save the excess energy produced by the Savonius Wind Turbine given it's great performance in energy density. In practice, multiple springs could be aligned in series to store a greater amount of power. The power can then be drawn from the opposite side of the spring. To allow power to be drawn and the spring to be wound at the same time, the input shaft could be connected at the hub of the spring, and the output shaft connected to the outside of the spring.[2]

The coil spring is loaded by using the excess energy produced by the wind turbine through a ratchet. If the spring is fully loaded the remaining energy could be used in some type of energy dissipator.

The materials chosen in our energy storage system were based on an in-depth analysis of atmospheric conditions, the mechanical and chemical properties of each material, temperature resistance and creep resistance.

The same, mentioned above in each part of the system are:

Inconel 718, with the addition of significant amounts of niobium and molybdenum, along with aluminum and titanium, alloy 718 has extremely high strength, excellent resistance to strain and stress cracking, and good corrosion resistance. [5][6]

We chose Li-S to produce the primary rechargeable batteries. This will be used to provide energy to the more power demanding functions such as sample extraction, sample analysis and compilation of atmospheric data; around 550 Wh. We chose this batteries given they are able to withstand the extreme temperatures of Venus and its excellent energy density(2735Wh/kg), about 200 to 500 Celsius degrees. Also this battery can be recharged using a system based on taking CO2 from Venus’s atmosphere[7]. Given this battery is currently in development we do not have the actual characteristics, but we expect it to have similar characteristics to the current SOP (State of Practice) batteries used in NASA missions with the difference of being able to withstand Venus high temperatures and energy density since it is rechargeable (see Figure 3).

Figure 3: State of practice (SOP) lithium-based primary batteries used in NASA missions [3]

Given the extreme pressure in Venus and its corrosive atmosphere, we propose placing the batteries in protective enclosures, and we expect the batteries to weight 20kg and occupy 19.5l of volume, and to recharge them 20 times to be able to comply with the Rover’s power requirements and more, having some contingency in mind.

{1} System that generates a controlled atmosphere inside the protective enclosure of the springs and the battery.

{2} Protective enclosure containing the batteries.

Firstly we write the general sustainability formula:

L =½ * r * S * C *L * v^2 eq.(1)

Where:

L: Lift

Cl: Lift coefficient

v: wind velocity

r: Density

After that, we calculate the force produced by the wind turbine with the following equation:

N =½ * r * S * {(v + u)^2 - 0,2 * (v - u)^2 } eq.(2)

Where:

v: wind speed

u: Rotation Speed

N: Power

The upper equation can be simplified, assuming coefficients of order 0.3 and rotating speed u= v/6. Obtaining the following equation:

N =½ * r * A * v^3 * h eq.(3)

Where:

N= power [kW]

r = air density [Kg / m3]

A= rotor frontal area [m2]

v= wind speed [m/s]

h = aerodynamic performance

Clearing for A, to obtain the area needed, we get:

A= (2*N) / (p * V^3* 𝛈) eq.(4)

We made extensive use of the data provided by the California Institute of Technology, which provided useful information about the expected power consumption values and several viable solutions to the problems presented on the Surface Rover. This allowed us to have the necessary information to comply with the power storage requirements of the challenge and the materials used to withstand the atmospheric conditions of Venus.

We also used data provided by the JPL and NASA to decide which batteries would best fit the necessities of our project, taking into account the current State Of Practice of batteries used in Nasa missions.

And finally we used some useful data provided by the CONAE investigators during the event, to better understand the processes and tests the surface Rover could be subjected to.

Our team chose this challenge because all our members are Aeronautical Engineering students and our interest is related to the design of space vehicles and components, considering it interesting to be able to test our qualities when working as a team designing the energy storage system for a Venus Rover.

First we focused on investigating the conditions of venus, after analyzing we could take understand what was the problem to be solved and what factors we should have into account. That way we started to organize ourselves by distributing tasks and setting meeting times to discuss among all of us how we were going to move forward. Brainstorming meetings!

Our first approach was to analyze the data provided by the space agencies in relation to the challenge, analyzing and choosing the available technologies to develop an efficient and safe energy system.

Our next Task was to design the wind power generation system according to the analyzed technical characteristics of the Rover AREE, for which we had to carry out all the necessary calculations to be able to meet the energy needs.

Finally we thought about the possibility that the same generator loads the springs to use them as auxiliary energy. While when designing the battery, it would be in charge of electrically driving the remaining systems.

We could say that this experience was very fruitful and enriching from an academic and social point of view, since we had the opportunity to interact with professionals and researchers from space agencies and companies that helped us in the challenge.

We believe that it was and will be of great importance in our professional development to be able to be useful members of society and in the future to participate in the development of space missions.

We would like to thank our teachers, tutors, CONAE researchers, and all the people who organized the Space Apps Challenge Cordoba, for accompanying us and for being willing to help us at all times.

[1] JAXA | Outline of Venus. (s. f.). Retrieved October 1, 2022, from https://www.jaxa.jp/countdown/f17/overview/venus_e.html

[2] Sauder et al. (2017). Automaton Rover for Extreme Environments.(Final Report). California Institute of Technology. https://www.nasa.gov/sites/default/files/atoms/files/niac_2016_phasei_saunder_aree_tagged.pdf

[3] Sarampudi et al. (2017). Energy Storage Technologies for Future Planetary Science Missions. (Report No. JPL D-101146). NASA. https://solarsystem.nasa.gov/system/downloadable_items/716_Energy_Storage_Tech_Report_FINAL.PDF

[4] Inconel – Density – Strength – Hardness – Melting Point. (n. d.). Material Properties. Retrieved October 1, 2022, from https://material-properties.org/inconel-density-strength-hardness-melting-point/

[5] Muraca, R. F. (1972, 1 abril). materials data handbook: inconel alloy 718 - NASA Technical Reports Server (NTRS). Recuperado 2 de octubre de 2022, de https://ntrs.nasa.gov/citations/19720022810

[6] Valbruna Stainless Steel. (s. f.). Steel AV718CRV. Recuperado 2 de octubre de 2022, de https://www.valbruna-stainless-steel.com/steels/9330

[7] NASA TechPort. (n.d.). Project Data. Retrieved October 2, 2022, from https://techport.nasa.gov/view/92914

#Venus, #Hades, #Rover, #Energy, #Catia, #Hardware

Your challenge is to design an energy storage system that will power a surface lander or rover on the surface of Venus for at least 60 days, so that there is a viable energy storage capability for long-duration exploration missions.