High-Level Project Summary

Humanity's inherent desire for exploration has now led us to the Red Planet, Mars. The visitor, an astronaut, must survive a year with only three 3-D printers and a pre-constructed habitat. Fusion Designers' plans will allow our astronauts to survive and thrive in a new world. With the help of printers producing reliable and practical tools, Fusion Designers will allow the astronaut to explore the foreign land and live comfortably within their habitat. Through various essential tools combined with furniture like a mars-designed bed and chair, our astronaut will leave Mars with a cheerful demeanor and greater knowledge about living on the Red Planet.

Link to Final Project

Link to Project "Demo"

Detailed Project Description

Fusion Designers created a multitude of objects to maximize the astronaut’s comfort and exploration abilities on Mars. Our designs were created with a variety of software including TinkerCAD, Fusion360, and Blender.

The following designs were made with certain assumptions in mind:

- We have adhesives (glue)

- There is only one astronaut in the habitat

- We have neodymium magnets at our disposal

- We have cobalt chromium for our metal 3D printers

- We have TPU (Thermoplastic polyurethane) and PA (Polyamide) filaments for our plastic 3D printer

Additionally, each of our designs follows a color scheme:

- Anything in gray will be created in metal.

- Anything in orange/brown will be created in plastic.

- Anything in blue will be created in concrete.

Tools:

To till the Martian soil for farming and mine the rocky grounds, we designed a metal shovel, pickaxe, and hoe, along with a plastic tool box to hold these items. In order to maximize resourcefulness, the handle to each of these tools is universal, so only one handle will be needed and can be easily replaced. The individual pieces of the tool can be screwed tightly into the handle, while the remaining pieces can be stored in a compact toolbox, which is magnetically covered by a plastic lid. The magnets are glued into the holes that are already indented into the box and lid corners. We used Tinkercad to design the tools and the toolbox.

To maintain sustainable construction of future furniture and habitat, we designed a plastic single piece hand drill based on antique hand drills. A simple yet effective drill that can easily be replaced as well features the screw in function like that of the farming/mining tools but for the metal drill bit. We used Tinkercad to design the hand drill and its bit.

To fix any issues with screws in other items we create, a screwdriver is necessary. The design of the screwdriver using a similar handle to the one used for the shovel, hoe, and pickaxe. However, this handle is much smaller. Through our design, the screwdriver has both a flathead and Phillips that can be attached to the same handle, which allows us to use them on multiple types of screws while minimizing materials used.

Another tool we designed were multiple metal wrenches that are able to serve many different purposes throughout the astronauts life on Mars. We designed two of these tools which serve different purposes. The first one, the combination wrench, is designed to be versatile in the Martian terrain. Its design is difficult to damage, and can be used in most scenarios where a wrench is required. The wrench can be utilized in the Martian soil, and will not suffer from the issues that can plague tools with more complicated gear systems. The other wrench designed is a monkey wrench with an integrated gear system. These gears can be used to tighten the grip the wrench has on an object. This allows the tool to be used primarily indoors, to repair or create anything that may be needed for the astronaut.

Furniture:

To comfortably rest at night, we created a bed for our astronaut. The bed frame is printed in concrete, and its inside fits 90 12cm x 12cm modules made out of plastic. The modules have 2.1cm x 2.1cm x 6cm springs in between the plastic surfaces to compress with the weight of the astronaut, and make the hard plastic surface softer. Creating our own mattress is ideal, as bringing a feather one from earth is not practical, given its considerate size. The springs should be able to support the full weight of the astronaut because on Mars, they would have the weight of a child on Earth.

Additionally, we designed a bench for another rest option for our astronaut to have at his disposal. The bench is created using concrete, with the measurements being 140 cm x 38 cm for the backrest, 140 cm x 35 cm for the seat, and 68 cm being the overall height. These measurements should be able to comfortably seat the astronaut, and provide them with an extra way to relax in their habitat.

Miscellaneous:

For entertainment purposes, we designed a Rubik's cube as well. This is a 56x56mm cube consisting of smaller movable cubes, 9 on each side. The Rubik's cube can provide the visitor to Mars with something to do in their free time. Tinkercad was used to design this project using dimensions from the real life figure. The cube will be created using the plastic 3D-Printer.

In the challenge prompt, our astronaut is said to be provided food for the year in his habitat. However, there is no mention of utensils for our astronaut to consume the food with. To fix this issue, our team designed both a simple plate and spork. Instead of creating a separate fork and spoon, we created a spork, which has utility of both utensils and minimizes materials used for this goal.

Spare Wheel:

Since we needed a spare wheel, we decided to design a rover that could go on a short mission. Unlike current rovers which use a combination of aluminum and titanium wheels, we have a smaller selection of materials. While we can't make the wheel indestructible, we can make it extremely easy to maintain. Given the extensive damage that the rover Curiosity received, we opted for a modular design. The inside of the wheel is made out of cobalt chromium while the outside is composed of eight PA plastic tire modules, which would be the ones in direct contact with the harsh Martian surface. Therefore, they are replaceable, and if they break down, they can be swapped using a simple slide in and out mechanism. Plastic was chosen for the outside of the wheel since it's repairable, allowing it to absorb impacts from the surface. Rather than an extremely durable wheel that transmits impact to the river itself, plastic is preferred as this is one of the only three 3D printable materials that would be suitable for this design. Screws were implemented as well to keep the modules in place.

Space Agency Data

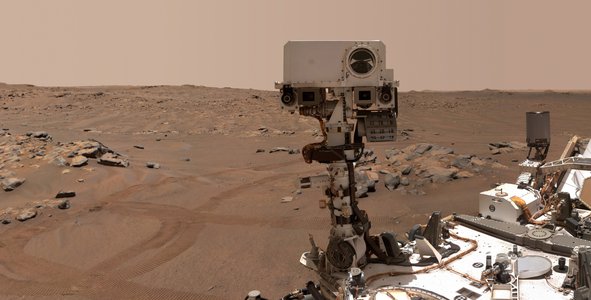

Fusion Designers used the previous rover mission on Mars as the backbone of the spare wheel design. However, we also considered that the astronaut would be on Mars in contact with the rover. As for the wheel size, we decided to use some of NASA's measurements given in the example wheel. Using pictures of NASA's Curiosity, Perseverance and Ingenuity, as well as China’s Zhurong rovers, we believed these examples fitted our measurements best.

https://www.jpl.nasa.gov/news/breaks-observed-in-rover-wheel-treads (NASA Open Data Used)

https://mars.nasa.gov/mars2020/spacecraft/rover/wheels/ (NASA Open Data Used)

https://www.asc-csa.gc.ca/eng/canadarm/ (Canada Space Agency Data Used)

https://www.asc-csa.gc.ca/eng/canadarm3/about.asp (Canada Space Agency Data Used)

Hackathon Journey

Fusion Designers' experience in the Space Apps challenge was tedious yet rewarding. Initially, we were inspired to choose this Mars design challenge given several members' experience in 3-D design as well as the creative appeal. In developing the project, we collaborated with each other and brainstormed/sketched out our ideas about what to include in a Martian habitat. We set up deadlines for ourselves to brainstorm, design, and finalize our parts of the project, allowing us to manage our time effectively. The work was split up between all six members of the team, each one of us designing a specific part that we formed during the brainstorming process.

While designing on one's own might seem easy at first, we all encountered many challenges and setbacks along the way. Some members were first-time users of 3D applications like Tinkercad, which in itself was easy to get a grasp of but a setback at first. In addition, we sometimes disagreed about what was significant about the project and took some shortcuts in our designs, compromising the final product. We also had disagreements over certain ideas and designs for parts of the project, including the wheel. In order for the designs to work in harmony, we realized that careful management and review of each one's work was crucial. We decided that we would work thoroughly and put in as much effort as possible, taking in account the criticism from our peers. We also made sure to coordinate with each other through our many hour-long Discord calls.

Our diverse backgrounds combined with our individual efforts led us to create a project that we felt proud of. Working with teammates across the hemisphere (Argentina & US), we were able to use virtual communication effectively to lend ideas. We learned so much more about Mars thanks to Iván's expertise not only in his knowledge of the planet but his dedicated research towards understanding the best factors for our habitat. His experience with applications like Matlab and dedication to designing an intricate and reliable habitat/rover is a blessing to the team's success. In addition, we thank Nico for his experience in 3D design through Blender and Fusion, not to mention the effort he put in marking the details of our designs. Lastly, we thank Chendur, Dan, and Andrew for their leadership and effort in contributing to the design as well as keeping the team in check. In all, we thank all members of Fusion Designers for their support in designing a Martian habitat that we are proud to deem trustworthy and viable.

References

- Wheel treads break on Curiosity rover - SpaceFlight Insider

- http://mobileimages.lowes.com/productimages/476c1c08-4b5c-47fb-bba6-ef91a7f4a499/09215229.jpg (Reference for our screwdrivers)

- https://sites.google.com/site/arunasirhmms/home/rubik-s-cube (Reference for Rubik's Cube)

- Hand drill inspiration

- Shovel piece design

- Drill inspiration

- https://currentaffairs.adda247.com/chinas-first-mars-rover-zhurong-successfully-lands-on-mars/ (Zhurong Rover Information)

- https://mars.nasa.gov/mars2020/spacecraft/rover/wheels/

- https://www.asc-csa.gc.ca/eng/canadarm/

- https://www.jpl.nasa.gov/news/breaks-observed-in-rover-wheel-treads

- https://www.asc-csa.gc.ca/eng/canadarm3/about.asp

Tags

#3DPrinting, #Mars, #Engineering