High-Level Project Summary

Our solution is focused on providing functional designs that have the potential of reducing costs of space exploration. By optimizing the designs we reduce the net weight of each piece, the waste of material as well as lowering By fixing the wheel transporting materials becomes feasible as well as resuming exploration.For the multi-purpose tool we are standardizing the screws and nuts used. So the tools we designed can be used anywhere in the habitat.The mallet is thought for the green-house as well as fixing and building things.The spade with pickaxe concept is for agriculture, sample collecting and material collection.Cutlery and crockery to provide astronauts with eating utensils.

Link to Project "Demo"

Detailed Project Description

Our proyect focus on providing solutions for any issue that might need to be solved by an astronaut on Mars during his one-year mission. This includes but is not limited to:

- a wheel substitution for the damaged one of the rover

The wheel is our most innovative proposal, since it is modular. This means it is made of pieces that can be changed, assembled and disassembled.

Imagine! In case your wheel gets damaged (again) instead of needing to change the whole wheel you just need to change a few pieces.

- mallet

Our only tool that gets the best of each of the three 3D printers, this tool is made out of components from the 3 different materials (concrete, plastic and metal). The head of the hammer is made out of concrete, the handle is plastic and has a metal core to reinforce it.

- multifunctional tool #1

Spade, pickaxe, hoe, saw (used for materials and samples recollection, as well as agriculture activities)

- multifunctional tool #2

Wrench and allen screwdriver (used for build, disassemble, repair)

We took special care on each proposal in order to meet the size requirements from the 3 different 3D printers. Also, thinking on convenience, efficiency and material saving every individual component was built for no supports to be used during the printing process. Another benefit is that none of the tool assemblys require neither bolts or glue, each tool has its own assembly mechanism.

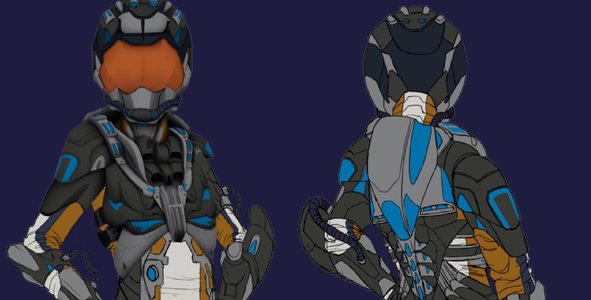

Each one of our designs was 3d modelled using SolidWorks 2020, then renders were created and edited on Procreate App.

Space Agency Data

After taking a close look to all the information avaliable, we noticed that astronaut's experience on analog missions provides way too useful feedback. The activities they perfom while being on analog missions generated our main question "what do they need for a mission?", and based on that we started a rainstorming process to generate innovative ideas.

Secondly, out team took some great inspiration from NASA's data, specifically 3D models. Having access to this models meant we were able to see what was previously desgined. We then used this inspiration to build 3d-printing friendly models, and even some multifunctional tools.

Hackathon Journey

If we were asked, we would describe our Space Apps experience with the word "knowledge".

On each step of our process, all the way from brainstorming to modelling, lead to new questions and us learning things. We had to ask ourselves something we never think about before, this led to incredibly entertaining and long talks between the members. Since our team has and engineering member and an arts member, having to fusion our ideas lead to teaching each other things from their own field.

Our team was inspired by the idea of joining engineering and art for the benefit of astronauts. From the very beginning our goal was to create designs that brought together desing and functionality.

We would love to thank our local leaders for the amazing experience provided. We noticed every small detail was really well taken care of, which made the experience even more enjoyable. From conferences, to reminders, FAQ's and mentoring, it was really surprising how hardly everyone worked to bring up this event.

References

https://nasa3d.arc.nasa.gov/models

https://www.nasa.gov/analogs

https://www.marssociety.org/topics/mars-analog/

Tags

#3dmodel #CAD #design #3Dprinting #Mars #plastic #concrete #metal