· The Martian crust consists mainly of volcanic basaltic rock. Martian soil also contains nutrients such as sodium, potassium, chloride, and magnesium. According to NASA, the crust is 10 to 50 kilometers thick.

· The mantle is largely dormant and is composed primarily of silicon, oxygen, iron, and magnesium, and probably has the consistency of a soft, stony paste. According to NASA, it is probably about 770 to 1,170 miles (1,240 to 1,880 km) thick.

· Mars regolith is mostly silica and iron oxide, with significant amounts of alumina, calcium oxide, and sulfur oxide. The composition varies from place to place on the planet's surface due to variability in asteroid impacts and weathering by wind and water.

· According to NASA Mars-1a is a very close replica of Martian soil. The simulant contains 43.48% silica and 16.08% iron oxide by weight, compared to average values measured on Mars of 45.41% silica and 16.73% iron oxide.

· Mars' red colour comes from iron oxide on the planet's surface.

To obtain pure iron, we would have to perform a chemical reaction that separates the

iron from the oxygen.

· First, analysis of meteorites on Mars suggests that the planet's mantle is about twice as rich in iron as Earth's mantle. The planet's distinct red color is caused by iron oxides on its surface. Second, its core is richer in sulfur. Third, the Martian mantle is richer in potassium and phosphorus than Earth's, and fourth, the Martian crust contains a higher percentage of volatile elements such as sulfur and chlorine than Earth's crust.

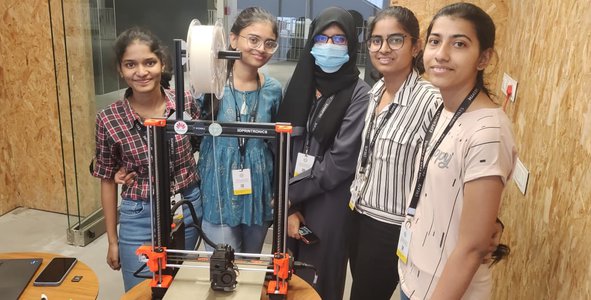

3D CONCRETE PRINTER

· A small amount of simulated crushed Martian rock mixed with a titanium alloy made a stronger, high-performance material in a 3D‑printing process that one day could be used on Mars to make tools or rocket parts.

· The parts were made by Washington State University researchers with as little as 5% up to 100% Martian regolith, a black powdery substance meant to mimic the rocky, inorganic material found on the surface of the red planet.

· While the parts with 5% Martian regolith were strong, the 100% regolith parts proved brittle and cracked easily. Still, even high-Martian content materials would be useful in making coatings to protect equipment from rust or radiation damage

· 3D printable concrete is actually a cement-based mixture of several materials, including super-plasticizers that remove water from the mix for faster drying and fibrous materials for improved strength.

· Superplasticizers (SPs), also known as high range water reducers, are additives used in making high strength concrete. Superplasticizers allow reduction in water content by 30% or more.

· The use of super plasticizers also made it possible to use the fly ash, slag and silica fume to produce high quality concrete.

· The use of plasticizers also produces a homogeneous and cohesive concrete without any tendency of segregation and bleeding.

· Martian soil can be used as an aggregates. As for feasible binder solution cement is commonly used on earth, the main chemical components of Portland cement are calcium oxide, silicon dioxide, iron oxide ,aluminium oxide and water.

· Cement can harden in air or water and we can firmly bond sand , stone and other materials together which makes it favourable construction material.

· Cementitious materials that have W/C ratio and a slump flow spread of 0.30 to 0.32 and 190 to 200 mm, respectively, were found to be optimal properties of the materials for extracting and layering the cementitious materials from the 3D printer by the laboratory testing.

· The testing proved that the adding 0.4 amount of sand, maximum size of 0.7mm, relative to cement produced suitable mortal mix which did not cause any bleeding or clogging while printing.

· The laboratory testing verified that adding 0.1% PVA fibers increased the quality of the printing by preventing shrinkage cracking.

TYPES OF 3D CONCRETE PRINTERS:

· GANTRY SYSTEM: A component of a printer’s frame, the gantry allows for movement along a horizontal axis. In other words, a gantry is the structure on a 3D printer that supports a sliding component.

· ROBOTIC ARM: combines a 3D printer head to extrude polymers, with a multi-axis robotic arm to create a much more flexible 3D printer than conventional models.

· MODULAR CONCRETE PRINTER: It has an interchangeable nozzle system that can accommodate different specifications.

METAL 3D PRINTER

The Wheel

Till now the number of rovers sent on Mars are Sojourner, Spirit and Opportunity, Curiosity, and Perseverance. The wheels of curiosity, each wheel is made of single sheet of aluminum. Aluminum was used because it was light weight, durable and impressively strong. But unfortunately as the surface of mars is rocky, with canyons, volcanoes, dry lake beds and craters all over it, the wheels have shown a sign of wear and tear. So, engineers redesigned the wheels for Perseverence , the wheels are narrower , bigger in diameter and are made of thicker aluminum.

The degradation of wheels implies us to search for new technologies. One of the technology we can use is “Shape Memory Alloy” for designing the Rover wheels. This Shape memory alloy also known as ‘Nitnol’ is made up of Nickel and Titanium. This alloy can act as a spring. A Shape memory alloy can return to its original shape when it is deformed. But the question is whether the wheel made up of shape memory alloy is 3d printable?